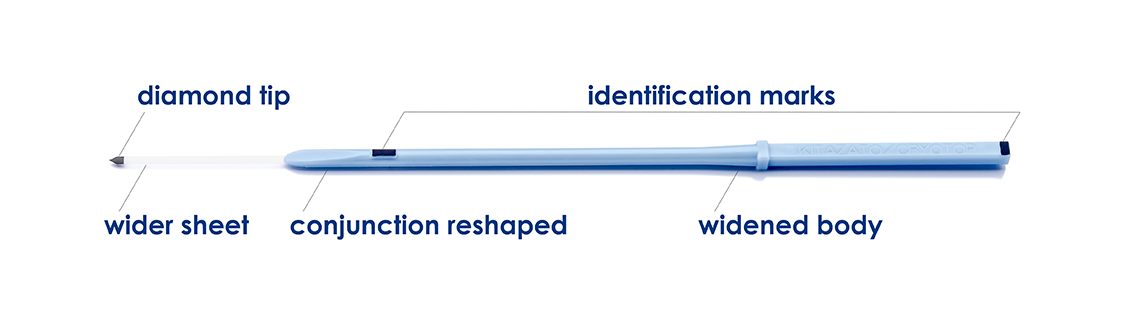

THE NEW CRYOTOP® IMPROVEMENT

Wider Strip: The strip’s been widened. Now, with a bigger surface, it is even easier to load the specimens.

Easier Insertion: The diamond tip, the reshaped conjunction between strip and handle and the widened body grant a smoother insertion into the coverstraw.

Identification Marks: The Cryotop® has now two identification marks on its upper surface, defining the side where the specimens should be loaded, if you are vitrifying, or are loaded, if you are thawing.

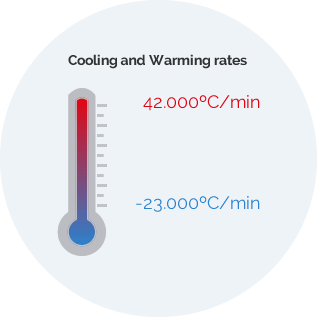

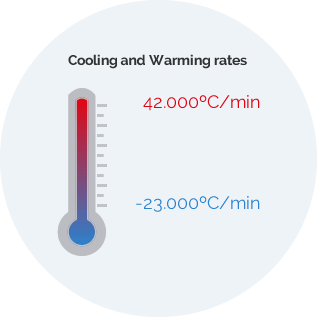

Cryotop® is a vitrification device consisting of a fine strip of transparent film attached to a plastic handle resistent to liquid nitrogen. Its design allows the loading of specimens for vitrification with a minimum volume (0.1 µl), providing the best Cooling and Warming rates on the market (-23,000ºC/minute and 42,000ºC/minute respectively) which in turn lead to the best survival rates.

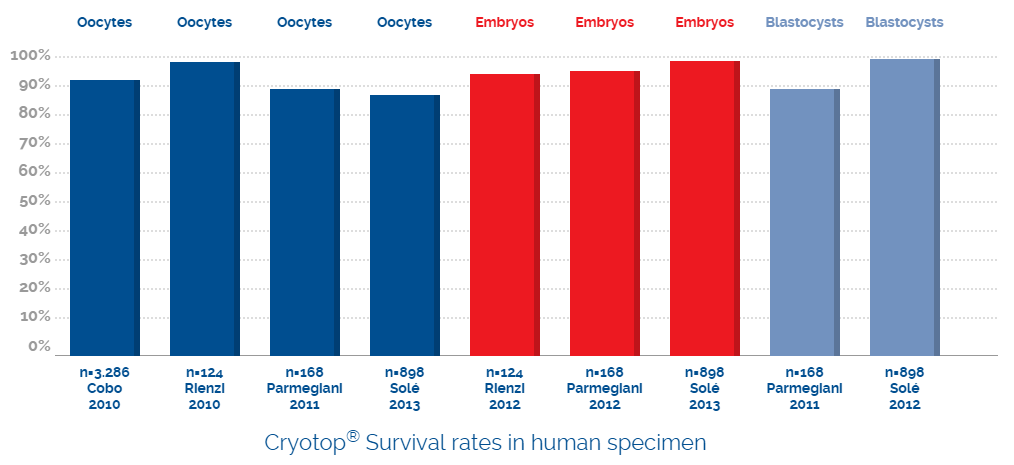

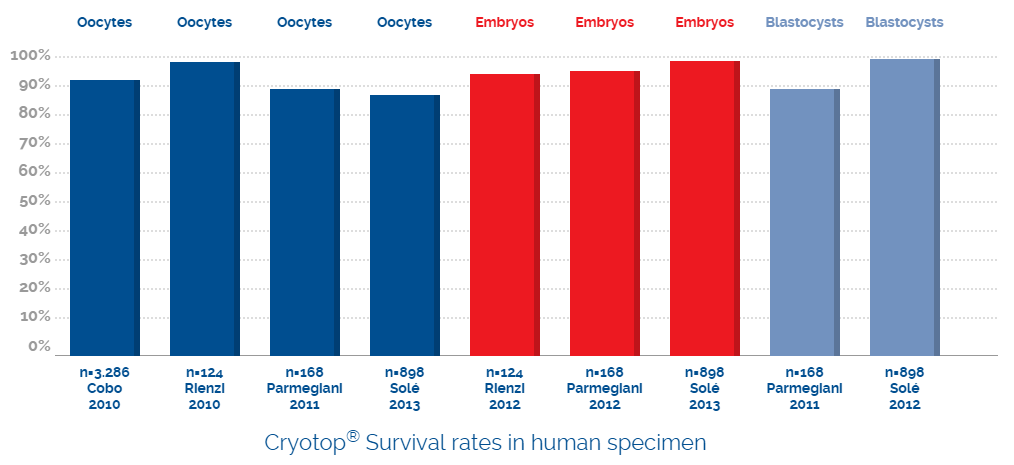

Highest survival rates

Cryotop® Method offers proof of its outstanding results. Our survival rates over 90% are backed up by numerous clinical studies with the biggest sample sizes in the market.

Main characteristics;

Allows up to 4 specimens to be loaded per device.

It has an external covering to protect the Cryotop® once vitrified. Tip with weight to prevent floating in liquid nitrogen.

Manufactured in malleable plastic resistant to liquid nitrogen.

Available in packs of 10 units.

Cooling Rack;

Cooling Rack;

Designed to contain the liquid nitrogen during vitrification. Metallic cover for the interior also available, allowing sterilisation before use.

Not just the best proven results on the market, now also the best user experience.

Not just the best proven results on the market, now also the best user experience.